CROWN BIT DIVERSIFY WATERWAYS

Impregnated Diamond Bit

Impregnated diamond bit, set with diamond inside the matrix, the most commonly useful style in mineral exploration, as they have the widest range of application.

>>Selection of high quality synthetic diamond to distribute better drilling performance.

>>The matrix layer of CROWN bit contains a reasonable distribution of diamond that are embedded in a metal powder to achieve better cutting performance.

>>Matrix height is diversified from 7mm to 16mm, depends on consumers' needs.

>>CROWN bit is designed to reach optimum penetration rates and bit life to help consumers cost- effectiveness and efficiency.

>>The optimum diamond size, concentration and matrix type are dependent on the hardness and abrasiveness of rock formation to be drilled.

>>The matrix layer of CROWN bit contains a reasonable distribution of diamond that are embedded in a metal powder to achieve better cutting performance.

>>Matrix height is diversified from 7mm to 16mm, depends on consumers' needs.

>>CROWN bit is designed to reach optimum penetration rates and bit life to help consumers cost- effectiveness and efficiency.

>>The optimum diamond size, concentration and matrix type are dependent on the hardness and abrasiveness of rock formation to be drilled.

Standard V ring type:

• Can be used on most impregnated core bits

• Great fluid circulation from the inside to the outside

• Available with wider or larger waterways

• Can be used on most impregnated core bits

• Great fluid circulation from the inside to the outside

• Available with wider or larger waterways

Turbo type:

• Greater ejection of fluids and cuttings

• Reduced contact area with the same flushing performance

• Recommended for higher rotation speeds

• Available with wider or larger waterways

• Greater ejection of fluids and cuttings

• Reduced contact area with the same flushing performance

• Recommended for higher rotation speeds

• Available with wider or larger waterways

Face Discharged type:

•Recommended for very soft and broken ground

•The face discharge ports offer excellent flushing to prevent blockages in the waterway channels

•Available with wider or larger waterways

•Recommended for very soft and broken ground

•The face discharge ports offer excellent flushing to prevent blockages in the waterway channels

•Available with wider or larger waterways

Vortex type:

•Recommended for very hard, abrasive and broken ground

•Recommended for very hard, abrasive and broken ground

MATRIX HEIGHT

*10mm height, the most common height design to ensure the bit life and stability.

*Suggest for medium-deep downhole drilling.

*Suggest for medium-deep downhole drilling.

*over 10mm, more efficiency for time saving of drillers and longer working life of bit.

*Suggest fordeep downhole drilling .

*Suggest fordeep downhole drilling .

*Work with down hole motor.

*Appropriate for direction drilling.

*Appropriate for direction drilling.

A/WL,B/WL,N/WL,H/WL,P/WL,NWL-2,NWL-3,NWL-TT,HWL-3,HWL-TT,PWL-3,PWL -TT, AWL-TK,BWL-TK

T2 Series: T2 46,T2 56,T2 66,T2 76,T2 86,T2 101

T6 Series: T6 76,T6 86,T6 101,T6 116,T6 131,T6 146, T6S 101,T6S 116

T Series: T36,T46,T56,T66,T76,T86

Z Series: Z46,Z56,Z66,Z76,Z86,Z101,Z116,Z131,Z146

B Series: B36,B46,B56,B66,B76,B86,B101,B116,B131,B146

WF Series: HWF,PWF,SWF,UWF,ZWF

WT Series: RWT,EWT,AWT,BWT,NWT,HWT

WM Series: EWM,AWM,BWM,NWM

WG Series: EWG,AWG,BWG,NWG,HWG

Others: NMLC,HMLC,LTK48,LTK60,BGM,NGM,ADBG,TBW,TNW, ATW,BTW,NTW,HTW,NXD3,AX,NX,NXC,AXT,T6H,4 9/16,NWD4,412F,SK6L146, TT46,TB56,TS116,CHD101

T2 Series: T2 46,T2 56,T2 66,T2 76,T2 86,T2 101

T6 Series: T6 76,T6 86,T6 101,T6 116,T6 131,T6 146, T6S 101,T6S 116

T Series: T36,T46,T56,T66,T76,T86

Z Series: Z46,Z56,Z66,Z76,Z86,Z101,Z116,Z131,Z146

B Series: B36,B46,B56,B66,B76,B86,B101,B116,B131,B146

WF Series: HWF,PWF,SWF,UWF,ZWF

WT Series: RWT,EWT,AWT,BWT,NWT,HWT

WM Series: EWM,AWM,BWM,NWM

WG Series: EWG,AWG,BWG,NWG,HWG

Others: NMLC,HMLC,LTK48,LTK60,BGM,NGM,ADBG,TBW,TNW, ATW,BTW,NTW,HTW,NXD3,AX,NX,NXC,AXT,T6H,4 9/16,NWD4,412F,SK6L146, TT46,TB56,TS116,CHD101

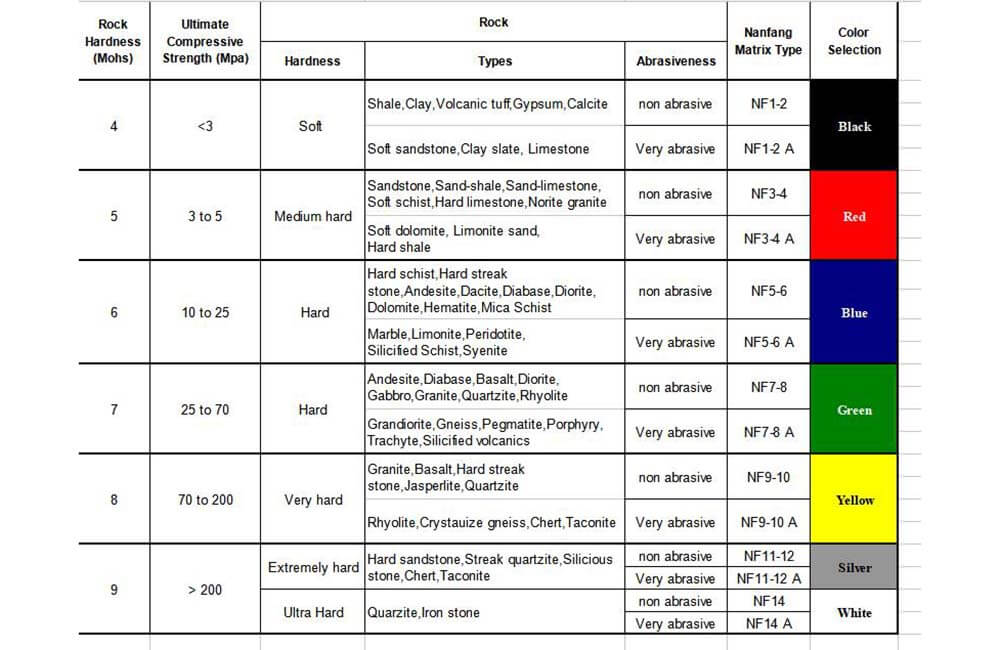

Impregnated Bit Matrix Selection chart

When order,please select the bits according to your rock formation, how hard? Abrasive or not?

For some special or complicated ground,we will need to customize the diamond bits according to the actual drilling conditions.

Some suggestions for better use of our diamond bits:

SOFT ROCK FORMATIONS

• Low RPM’s

• Large diamonds/cutters

• Large waterways for better flushing and higher GPM flow rates

• Hard matrix for longer bit life

HARD ROCK FORMATIONS

• High RPM’s

• Small diamonds/cutters

• Small waterways

• Soft matrix to expose more cutting elements

For some special or complicated ground,we will need to customize the diamond bits according to the actual drilling conditions.

Some suggestions for better use of our diamond bits:

SOFT ROCK FORMATIONS

• Low RPM’s

• Large diamonds/cutters

• Large waterways for better flushing and higher GPM flow rates

• Hard matrix for longer bit life

HARD ROCK FORMATIONS

• High RPM’s

• Small diamonds/cutters

• Small waterways

• Soft matrix to expose more cutting elements

Feedback form contact with us

Related Product