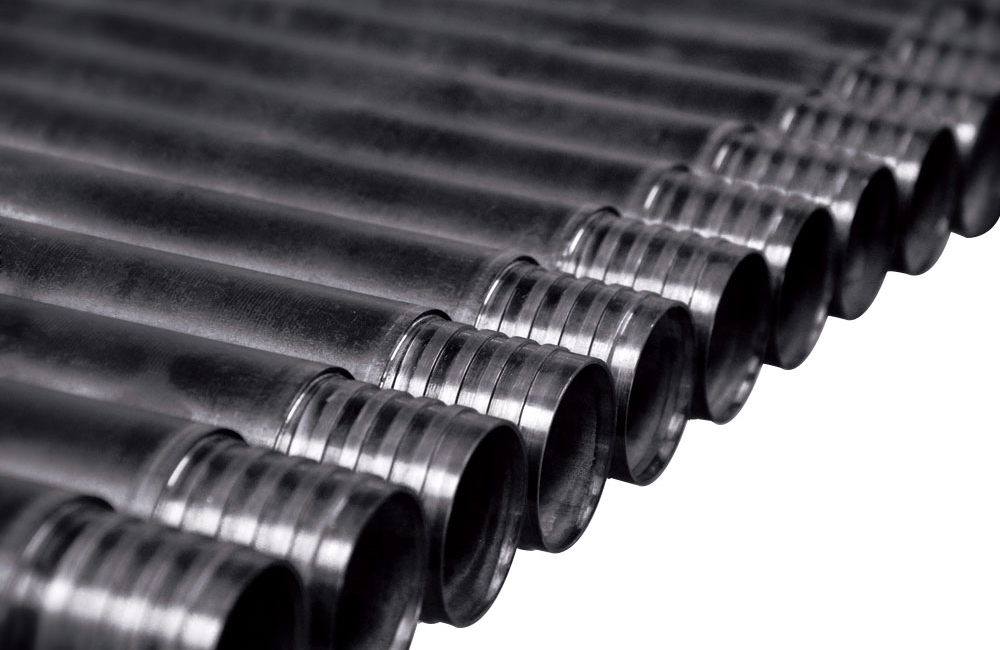

>>Ultimate tensile strength, yield strength, high precision and good straightness provide the best performance under different drilling conditions.

>>Case hardening on rod’s end protects thread connection and increases its wear resistance and rod life.

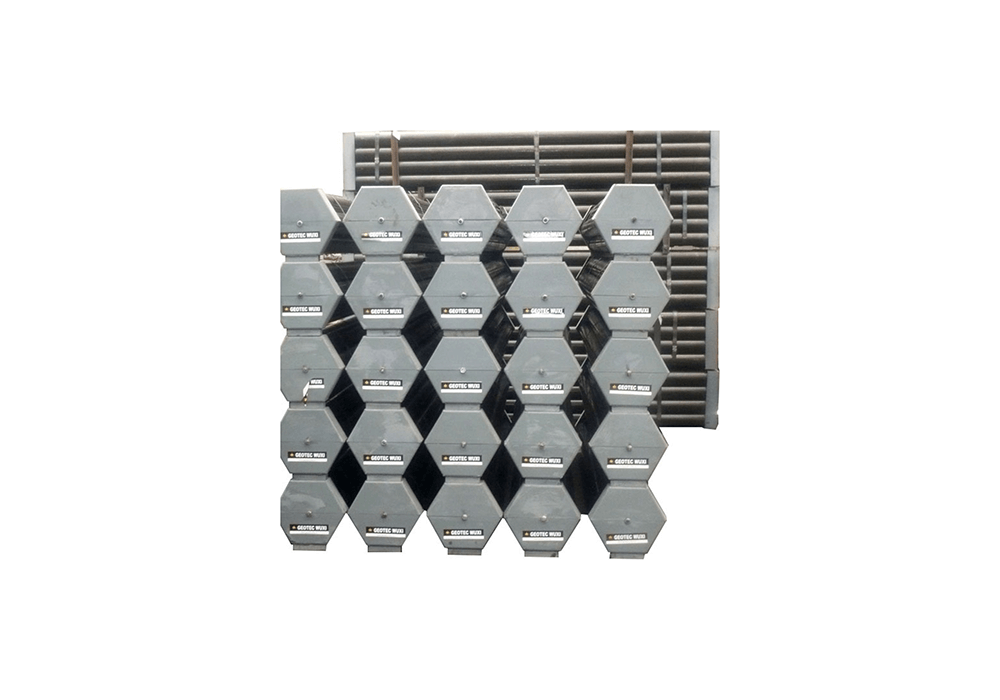

>>Based on 30 years drill rod manufacturing experience, Getoec provides the most cost-efficient products.

|

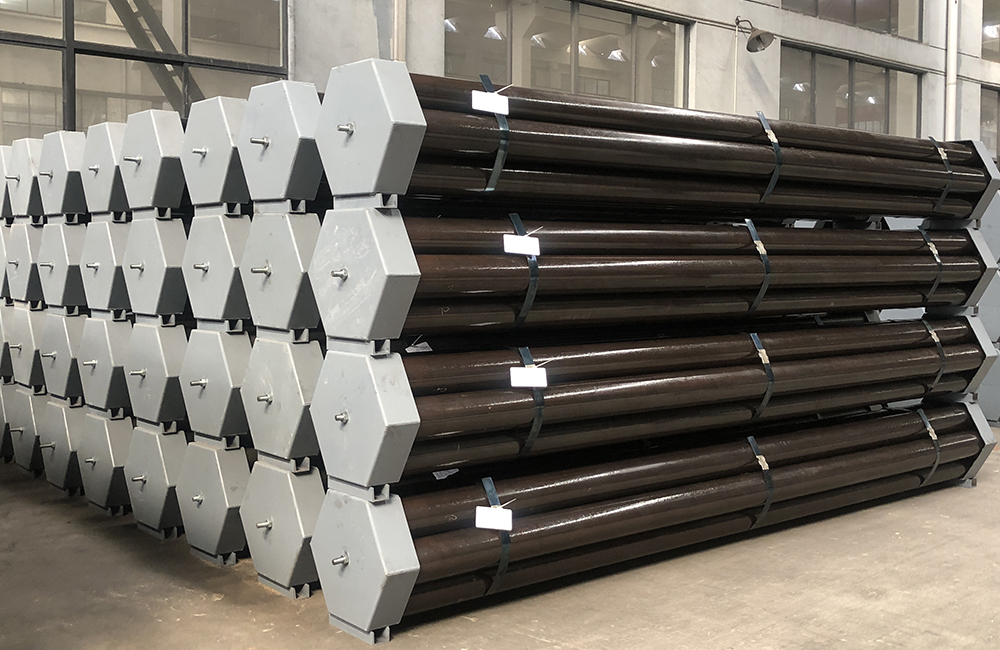

DIMENSION |

LENGTH |

WEIGHT/PC |

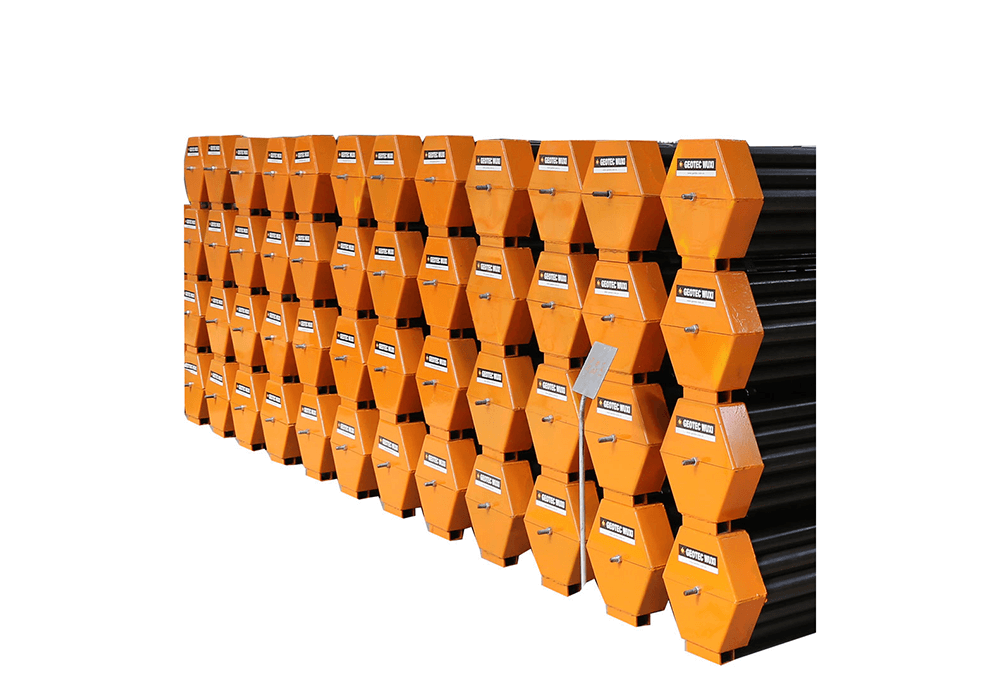

PCS/BUNDLE |

BUNDLE WEIGHT |

BUNDLE |

BUNDLE VOLUME |

20ft CONTAINER LOADING |

|

B/WL |

3.0m |

18 |

64 |

1180 |

3120 x 530x 555 |

1.0 |

1024pcs /16 bundles |

|

|

1.5m |

9 |

64 |

590 |

1580 x 530x 555 |

0.6 |

|

|

N/WL |

3.0m |

24 |

36 |

894 |

3120 x 530x 555 |

1.0 |

720pcs /20 bundles |

|

|

1.5m |

12 |

36 |

447 |

1580 x 530x 555 |

0.6 |

|

|

H/WL |

3.0m |

38 |

25 |

980 |

3120 x 530x 555 |

1.0 |

500pcs /20 bundles |

|

|

1.5m |

19 |

25 |

490 |

1580 x 530x 555 |

0.6 |

|

|

HWT |

3.0m |

52 |

16 |

862 |

3120 x 520 x 520 |

1.0 |

320pcs /20 bundles |

|

|

1.5m |

26 |

16 |

431 |

1580 x 520 x 520 |

0.6 |

|

|

|

BWL |

NWL |

HWL |

PWL |

BQZ |

NQZ |

HQZ |

|

Max. Depth Capacity (m) |

2360 |

1950 |

1440 |

1260 |

3200 |

2800 |

2300 |

|

Outer Diameter (mm) |

56 |

70.5 |

89.45 |

114.3 |

56 |

70.5 |

89.45 |

|

Inner (Tool joi nt) Diameter (mm) |

46.4 |

60.3 |

77.8 |

101.6 |

46.4 |

60.3 |

77.8 |

|

Wall Thickness (mm) |

4.8 |

5.1 |

5.9 |

6.4 |

4.8 |

5.1 |

5.9 |

|

Rod Weight per kg/3m |

18 |

24 |

38 |

52 |

18 |

24 |

38 |

|

Yield strength Min. |

680 |

985 |

1030 |

1040 |

680 |

985 |

1030 |

|

Tensile strength Min. |

800 |

1060 |

1120 |

1130 |

800 |

1060 |

1120 |

|

Elongation % |

18/20 |

16/17 |

15/16 |

15/16 |

18/20 |

16/17 |

15/16 |

|

Joint traction to failure |

345 |

412 |

685 |

699 |

360 |

437 |

690 |

|

Joint torque to failure |

6 |

9 |

20 |

20 |

7 |

10 |

21 |

* Performance data calculated according to theoretical and Ideal condition. Actual performance may vary depending on real operating conditions and drilling practices.

Make sure to lubricate the threads with grease to prolong the life of the rods and to prevent wear and galling. Special thread lubricant is the best.

Check the threads on the drill rods regularly. If the threads are damaged they can damage other rods they are connected to.

If the threading on one rod should get damaged during making of joint, both rods should be replaced.

|

Wireline Series |

A/WL, B/WL, N/WL, H/WL, HWT, NT, HT, PT, BQZ, NQZ, HQZ |

|

Metric Series |

33, 42, 50, 60, 75, 89, 114 |

|

"W" Design |

AW, BW, NW |

|

"WJ" Design |

AWJ, BWJ, NWJ |

|

Others |

BTW, NTW, HTW, LTK48 |

* Our Rods are high in quality and low in price.

* We always have large quantity of drill rods in stock.